Here's the web site URL https://www.wencerl.com. Wencerl is a leading provider of

Conclude Mills: Multipurpose Equipment for Specific Substance Removing

Square Stop Mills: Ideal for producing sharp corners and flat-bottomed cavities. Ball Nose Close Mills: Great for 3D contouring and sculpting sophisticated surfaces. Corner Radius Stop Mills: Merge the functions of square and ball nose mills for included strength and flexibility. Roughing End Mills: Created for quick product removal with minimal heat generation. - Finishing End Mills: Give easy finishes and tight tolerances in fragile functions.

Milling Resources: Essential Parts for Effective Milling Functions

Facial area Mills : Utilized for machining flat surfaces and producing a great finish.Shell Mills: Flexible tools that could be employed for each roughing and finishing functions. Slab Mills : Suited to eradicating significant amounts of fabric from the workpiece.Conclude Mills : Provide flexibility in slicing various products and styles.- Fly Cutters: Provide a Charge-efficient Remedy for attaining a easy surface complete.

Resource Holders: Making sure Balance and Precision in Machining

Collet Chucks: Offer higher clamping pressure and are ideal for Keeping compact-diameter resources. - Conclude Mill Holders: Created to securely hold close mills and limit Software runout.

Shell Mill Arbors : Utilized to mount shell mills onto the device spindle.- Drill Chucks: Allow for for speedy alterations concerning drills and various instruments.

Swift Change Instrument Posts: Allow fast tool changes, lowering downtime in CNC operations.

Precision Slicing Tools: Attaining Significant Accuracy in Machining

Carbide Tools : Offer fantastic hardness and use resistance for prolonged Resource everyday living.Cermet Instruments : Give top-quality surface area finish and are perfect for large-pace machining.Substantial-Speed Metal (HSS) Resources: Flexible and cost-effective, suitable for a wide range of apps. - Ceramic Tools: Effective at withstanding high temperatures and are employed for tricky materials machining.

Polycrystalline Diamond (PCD) Equipment: Give Fantastic use resistance for machining non-ferrous components.

Threading Applications: Producing Internal and Exterior Threads with Precision

Thread Mills : Employed for creating inside and exterior threads with higher precision.- Tap Drills: Give the proper hole dimension for tapping operations.

Die Heads : Enable for speedy and specific thread cutting in handbook functions.Threading Inserts : Replaceable reducing edges for efficient thread generation.Chasers: Employed in lathes for cutting threads on cylindrical workpieces.

different types of cutting tools

Drilling Instruments: Important for Producing Holes in Various Products

Twist Drills: Normally used for drilling holes in metallic, Wooden, and plastic. Center Drills: Made use of to create a conical hole for correct centering with the workpiece. Phase Drills: Allow for drilling numerous hole sizes without having shifting applications. Spade Drills: Suitable for deep hole drilling with significant substance removing rates. Gun Drills : Created for precision drilling of deep holes with tiny diameters.

Turning Equipment: Shaping Resources with Rotational Movement

Turning Inserts: Replaceable cutting edges for turning operations. Parting Resources: Accustomed to Slash off sections of a workpiece during turning. Dull Bars : Allow for for inside diameter machining with large precision.Grooving Equipment: Produce grooves and slots within the workpiece. Knurling Resources: Generate textured patterns on cylindrical surfaces for enhanced grip.

Reducing Instrument Resources: Choosing the Proper Content for your Occupation

Significant-Velocity Metal (HSS) : Provides superior toughness and it is appropriate for common-objective machining.Cemented Carbide: Delivers substantial hardness and have on resistance for extended Resource everyday living. Cermet: Brings together ceramic and metallic products for enhanced area complete. Ceramic : Effective at withstanding high temperatures for machining challenging components.- Polycrystalline Diamond (PCD): Delivers Outstanding dress in resistance for non-ferrous substance machining.

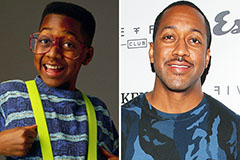

Jaleel White Then & Now!

Jaleel White Then & Now! Andrea Barber Then & Now!

Andrea Barber Then & Now! Elin Nordegren Then & Now!

Elin Nordegren Then & Now! Marcus Jordan Then & Now!

Marcus Jordan Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!