Here's the website URL https://www.wencerl.com. Wencerl is a leading service provider of reducing instruments, presenting a wide array of items which includes

Close Mills: Multipurpose Tools for Specific Substance Elimination

- Square Finish Mills: Perfect for producing sharp corners and flat-bottomed cavities.

Ball Nose Finish Mills : Ideal for 3D contouring and sculpting complicated surfaces.- Corner Radius Finish Mills: Merge the options of sq. and ball nose mills for additional strength and versatility.

- Roughing Finish Mills: Made for quick material removal with small warmth technology.

Ending Conclusion Mills: Offer clean finishes and limited tolerances in fragile functions.

Milling Instruments: Vital Components for Successful Milling Operations

Face Mills : Employed for machining flat surfaces and developing a high-quality complete.Shell Mills: Functional equipment which might be utilized for the two roughing and finishing operations. Slab Mills: Suitable for getting rid of massive quantities of material with the workpiece. Close Mills: Provide flexibility in chopping numerous elements and designs. Fly Cutters : Offer a cost-efficient Alternative for attaining a smooth surface area end.

Software Holders: Ensuring Stability and Precision in Machining

Collet Chucks: Offer superior clamping pressure and are ideal for Keeping tiny-diameter resources. Stop Mill Holders: Intended to securely hold stop mills and decrease Resource runout. Shell Mill Arbors : Accustomed to mount shell mills on to the equipment spindle.Drill Chucks: Enable for quick variations concerning drills as well as other resources. Brief Transform Tool Posts: Help quick Instrument variations, cutting down downtime in CNC functions.

Precision Chopping Equipment: Attaining Significant Precision in Machining

Carbide Equipment : Give great hardness and put on resistance for extended Software life.Cermet Equipment: Give superior surface area complete and are perfect for high-speed machining. Large-Pace Metal (HSS) Tools : Flexible and price-successful, appropriate for an array of apps.Ceramic Applications: Effective at withstanding superior temperatures and are utilized for difficult product machining. Polycrystalline Diamond (PCD) Applications : Offer Fantastic dress in resistance for machining non-ferrous products.

Threading Instruments: Building Interior and External Threads with Precision

Thread Mills: Useful for developing inside and external threads with large precision. Tap Drills: Provide the proper gap dimension for tapping functions. Die Heads: Make it possible for for swift and specific thread cutting in handbook functions. Threading Inserts: Replaceable slicing edges for economical thread generation. Chasers: Used in lathes for reducing threads on cylindrical workpieces.

Drilling Instruments: Important for Producing Holes in A variety of Materials

Twist Drills: Frequently useful for drilling holes in steel, Wooden, and plastic. Heart Drills: Employed to create a conical gap for accurate centering on the workpiece. Step Drills: Permit for drilling multiple hole dimensions without switching instruments. Spade Drills: Ideal for deep hole drilling with superior materials removal fees. Gun Drills : Made for precision drilling of deep holes with little diameters.

milling tool holder types

Turning Applications: Shaping Materials with Rotational Motion

Turning Inserts: Replaceable cutting edges for turning functions. - Parting Instruments: Accustomed to Lower off sections of the workpiece all through turning.

Dull Bars: Allow for for interior diameter machining with significant precision. Grooving Tools: Build grooves and slots during the workpiece. Knurling Applications: Make textured patterns on cylindrical surfaces for enhanced grip.

Cutting Device Supplies: Deciding on the Appropriate Product to the Career

Significant-Velocity Steel (HSS): Gives great toughness and is particularly suitable for typical-reason machining. Cemented Carbide : Delivers higher hardness and have on resistance for extended Device daily life.Cermet: Brings together ceramic and metallic components for enhanced floor end. - Ceramic: Able to withstanding higher temperatures for machining really hard resources.

Polycrystalline Diamond (PCD): Features Excellent wear resistance for non-ferrous materials machining.

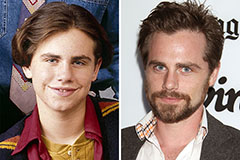

Rider Strong Then & Now!

Rider Strong Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Danny Pintauro Then & Now!

Danny Pintauro Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!