Here's the website URL https://www.wencerl.com. Wencerl is a number one provider of

Conclude Mills: Flexible Applications for Precise Product Elimination

Sq. Conclude Mills : Perfect for generating sharp corners and flat-bottomed cavities.Ball Nose Conclude Mills: Perfect for 3D contouring and sculpting complicated surfaces. Corner Radius Conclude Mills : Blend the attributes of sq. and ball nose mills for extra energy and flexibility.Roughing Stop Mills: Designed for immediate product elimination with negligible heat generation. Finishing Close Mills : Supply easy finishes and restricted tolerances in sensitive operations.

Milling Applications: Important Components for Successful Milling Functions

Experience Mills: Employed for machining flat surfaces and producing a high-quality finish. Shell Mills : Adaptable resources which might be used for the two roughing and ending operations.Slab Mills: Well suited for eradicating big amounts of fabric from the workpiece. Conclusion Mills : Provide versatility in reducing a variety of supplies and styles.- Fly Cutters: Provide a Price tag-efficient solution for reaching a easy surface finish.

precision cutting

Device Holders: Guaranteeing Stability and Precision in Machining

Collet Chucks : Present higher clamping power and are ideal for Keeping small-diameter applications.- Close Mill Holders: Meant to securely hold end mills and lessen Software runout.

Shell Mill Arbors: Used to mount shell mills onto the equipment spindle. Drill Chucks : Permit for speedy modifications concerning drills along with other instruments.- Fast Modify Resource Posts: Allow fast Device alterations, minimizing downtime in CNC functions.

Precision Reducing Applications: Achieving Superior Accuracy in Machining

Carbide Resources : Offer excellent hardness and dress in resistance for prolonged tool life.Cermet Resources: Supply exceptional surface end and are ideal for significant-speed machining. - Superior-Speed Metal (HSS) Instruments: Adaptable and cost-powerful, suitable for a wide array of purposes.

Ceramic Resources : Capable of withstanding large temperatures and they are used for hard content machining.Polycrystalline Diamond (PCD) Resources : Provide exceptional dress in resistance for machining non-ferrous products.

Threading Applications: Developing Inner and External Threads with Precision

Thread Mills: Employed for creating internal and exterior threads with large accuracy. Tap Drills: Provide the correct gap size for tapping functions. Die Heads: Allow for rapid and specific thread chopping in guide operations. Threading Inserts: Replaceable reducing edges for economical thread creation. - Chasers: Utilized in lathes for reducing threads on cylindrical workpieces.

Drilling Tools: Important for Generating Holes in Many Products

- Twist Drills: Usually employed for drilling holes in steel, Wooden, and plastic.

Centre Drills: Utilised to create a conical gap for precise centering in the workpiece. Move Drills: Allow for drilling multiple hole measurements with no transforming equipment. Spade Drills: Ideal for deep gap drilling with high substance removal fees. Gun Drills: Designed for precision drilling of deep holes with tiny diameters.

Turning Resources: Shaping Materials with Rotational Movement

- Turning Inserts: Replaceable chopping edges for turning operations.

Parting Tools: Accustomed to Minimize off sections of a workpiece throughout turning. Unexciting Bars : Allow for interior diameter machining with large precision.Grooving Tools: Develop grooves and slots inside the workpiece. Knurling Tools: Deliver textured styles on cylindrical surfaces for enhanced grip.

Reducing Resource Components: Deciding on the Proper Product for your Job

Higher-Velocity Steel (HSS): Offers very good toughness and it is well suited for general-objective machining. Cemented Carbide : Supplies large hardness and use resistance for extended Device lifetime.Cermet : Combines ceramic and metallic materials for enhanced area finish.Ceramic: Able to withstanding substantial temperatures for machining hard components. Polycrystalline Diamond (PCD): Delivers Fantastic dress in resistance for non-ferrous content machining.

Jennifer Grey Then & Now!

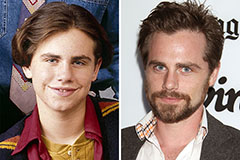

Jennifer Grey Then & Now! Rider Strong Then & Now!

Rider Strong Then & Now! Tiffany Trump Then & Now!

Tiffany Trump Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!