Here is the website URL https://www.wencerl.com. Wencerl is a number one company of

End Mills: Multipurpose Resources for Specific Product Elimination

Sq. Conclusion Mills: Perfect for developing sharp corners and flat-bottomed cavities. - Ball Nose End Mills: Great for 3D contouring and sculpting elaborate surfaces.

Corner Radius Stop Mills: Combine the capabilities of sq. and ball nose mills for included energy and flexibility. Roughing Conclude Mills: Created for speedy product removing with nominal heat technology. Ending Finish Mills : Give sleek finishes and limited tolerances in delicate functions.

edge cutting tool

Milling Tools: Vital Parts for Economical Milling Functions

Encounter Mills : Useful for machining flat surfaces and generating a wonderful finish.Shell Mills: Flexible applications that can be useful for both equally roughing and finishing functions. Slab Mills : Ideal for taking away large quantities of fabric in the workpiece.Stop Mills: Supply flexibility in reducing several supplies and shapes. Fly Cutters: Provide a Price-successful Alternative for reaching a sleek area end.

Software Holders: Guaranteeing Stability and Precision in Machining

Collet Chucks: Offer significant clamping pressure and are ideal for holding smaller-diameter tools. Conclusion Mill Holders: Designed to securely hold finish mills and reduce Device runout. Shell Mill Arbors: Utilized to mount shell mills on to the equipment spindle. Drill Chucks: Permit for quick changes amongst drills as well as other applications. Fast Alter Tool Posts: Allow immediate Instrument adjustments, lowering downtime in CNC operations.

Precision Slicing Equipment: Accomplishing Large Precision in Machining

Carbide Instruments: Provide outstanding hardness and wear resistance for extended Instrument daily life. Cermet Resources: Give outstanding surface finish and are perfect for large-pace machining. Substantial-Pace Steel (HSS) Resources: Adaptable and cost-efficient, well suited for a variety of apps. Ceramic Applications: Capable of withstanding significant temperatures and so are used for really hard substance machining. Polycrystalline Diamond (PCD) Applications: Provide Fantastic wear resistance for machining non-ferrous supplies.

Threading Resources: Developing Internal and Exterior Threads with Precision

Thread Mills: Used for making inside and exterior threads with superior accuracy. Tap Drills: Give the correct hole dimension for tapping operations. - Die Heads: Let for brief and specific thread reducing in guide functions.

Threading Inserts : Replaceable cutting edges for effective thread generation.Chasers: Employed in lathes for slicing threads on cylindrical workpieces.

Drilling Equipment: Essential for Producing Holes in A variety of Elements

Twist Drills: Normally utilized for drilling holes in metal, wood, and plastic. Centre Drills: Employed to create a conical hole for accurate centering with the workpiece. Action Drills: Make it possible for for drilling numerous gap dimensions with no switching equipment. Spade Drills: Ideal for deep gap drilling with superior material removing charges. Gun Drills : Made for precision drilling of deep holes with little diameters.

Turning Equipment: Shaping Components with Rotational Motion

Turning Inserts: Replaceable chopping edges for turning operations. Parting Resources: Used to Minimize off sections of the workpiece all through turning. Uninteresting Bars: Allow for inner diameter machining with higher precision. Grooving Tools: Build grooves and slots in the workpiece. Knurling Resources : Deliver textured styles on cylindrical surfaces for enhanced grip.

Slicing Software Components: Picking out the Proper Material for that Career

Superior-Speed Metal (HSS): Features fantastic toughness and is particularly appropriate for common-intent machining. Cemented Carbide: Supplies large hardness and have on resistance for extended Resource existence. Cermet: Combines ceramic and metallic supplies for improved surface area end. Ceramic: Effective at withstanding substantial temperatures for machining difficult elements. Polycrystalline Diamond (PCD): Delivers Outstanding put on resistance for non-ferrous product machining.

Edward Furlong Then & Now!

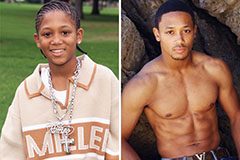

Edward Furlong Then & Now! Romeo Miller Then & Now!

Romeo Miller Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Nancy McKeon Then & Now!

Nancy McKeon Then & Now!